Using my 3D printer to make gifts for my wedding

I have been MIA for more than half a year now. One reason for my absence (among multiple others) is that I was preoccupied planning my own wedding. Having finally regained my free time, I have come back (now a married man) to tell the story of how I managed to impose my 3D printing hobby onto my wedding plans.

Motivation & Setup

My wife and I come from different origins, and it was during our preparations for our wedding, that she told me it was custom in her culture to offer the wedding guests small souvenirs, as a token of gratitude for their attendance. When I enquired what kind of souvenirs it was customary to offer, she told me it could be anything to commemorate the special day. Examples included towels with the initials of the young married couple, or canteens with an engraving of the date of the special day, and so on.

Figure 1: Prusa MK4 3D printer

Figure 1: Prusa MK4 3D printer

My last article contained the first mention of my 3D printer. If you are curious I own a Prusa MK4. Not that this is the article for it, but I chose to Prusa for the reliability of their printers, and their printers being fully operational offline, without requiring a smartphone application.

By the time my wife and I had our discussion, I had owned my printer for a year and a half already. During that period I had managed to dabble a bit in 3D-design, using FreeCAD as my CAD software. I chose FreeCAD over the many other available solutions, because I am deadly afraid of using a CAD software which can lock me out of my designs at any time depending on whether or not I have paid a subscription fee. FreeCAD being published under a free and open-source license allows me to rest assured that this will never be the case. Of course, this peace of mind comes at a price, as I have found it quite difficult to work around FreeCAD’s quirks. However, thanks to a very rich community of like-minded hobbyist, I have found the task less daunting.

With that short intermission out of the way, I think you can guess that it didn’t take me long to suggest to my -then- Fiancée to design and make our wedding souvenirs ourselves, with a little help from my 3D printer. On top of being a great opportunity to improve my 3D design skills, I thought this would be a unique chance to sneak a peek at what prototyping a real physical product is like, considering I would be making at least one hundred units of each gift. Finally, my wife and I both agreed that hand-made souvenirs, would definitely make for more memorable gifts for our guests.

The gifts

After a few brainstorming sessions, we settled on the following three gifts:

Figure 2: Our inspiration for the commemorative candle

Figure 2: Our inspiration for the commemorative candle

- A handmade scented candle in a solid mold in the shape of an infinity sign. Figure 2 shows our main inspiration for this souvenir, which we had stumbled upon online while we were searching for ideas. We though I could handle designing the mold, while my wife would handle melting the wax and affixing the wick.

One change which we thought would make the gift much more personal, was to replace the “you” and “me” in the original design with our names. - A handmade soap bar that would be engraved with the date of our wedding. Here again, the idea was for me to make the molds that would leave the imprints on the bars of soap, and for my wife to make the soap itself.

- The final gift, which for me was the most interesting to make , was a bed-side lamp. The lamp would be in the shape of a picture frame, but instead of a picture it would contain a lithophane plaque made from the wedding invitation we had sent to our guests.

In the following sections, I would like to give more details about the design process of the different gifts, and to address some aspects I found to be most interesting about it. One gift I will not be covering further is the scented candle, as I don’t want to share my wife’s and my name on the public Internet. Blurring our names made for ugly pictures that I felt did not do our work justice, and I am not unhinged enough to redo the design (along with all the involved iterations) using fake names.

Handmade soap

Initially, I had thought that, out of the three gifts, this would be the easiest to design. The shape of the bar of soap itself is a simple rectangle, and the imprint was also quite straight-forward: The date of the wedding underlined by a simple symbol of two interlinked wedding bands. The process we had in mind was to bulk order raw soap base, melt it, mix it with colorant and essential oils, then pour it into the mold and let it harden into the desired shape.

I immediately thought that a hard shell mold would not be usable, as it would make it very hard to extract the hardened bar. Instead, I thought this would be a perfect usecase for a silicon mold, as its flexibility would allow to “pop” the hardened bars of soap effortlessly once hardened. As such, the mold making process now involved first making a hardshell mold (using my 3D printer), which I would only use to make a soft silicon mold, which I then would use to make the soap bars.

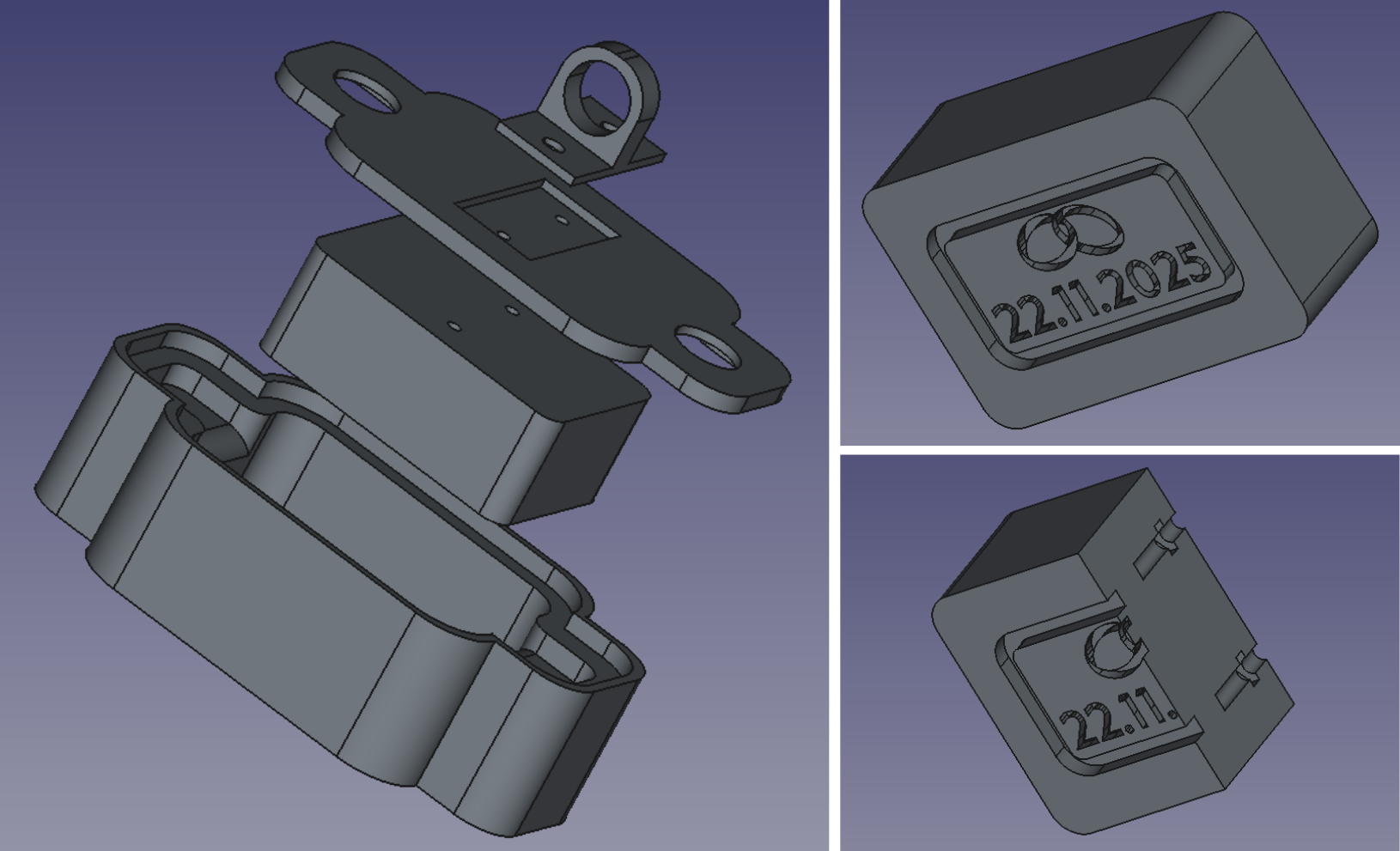

I started my design by first making a model of the bar of soap (top right of Figure 3), and building the mold around it. As is the case with all designs destined to be 3D-printed, I had to make sure the final part would be printable, as such the design of the mold included four easily printable separate pieces, which from bottom to top in the left section of Figure 3 are as follows:

- The “main” part of the mold is the bathtub looking-like piece. Its dimensions were calculated by leaving a

3mmspace around the soap model in each direction. This space would be later filled with silicon. - The “middle” part is based off the soap-bar model, with one slight modification. As shown on the bottom right part of Figure 3, the model includes two holes which are used to screw it to the remaining two top pieces. Additionally, two pockets have been made inside the model to house two

M3hexagonal nuts which would be used (along with matching screws) to hold this piece suspended in the “main” part. These nuts could be added to the printed object, by inserting a pause at the right time during the print process (using the slicer software). - The last two parts are the “top” cover and the “handle”. The two larger holes in the top cover are to be used for pouring the silicone into the mold. The handle was supposed to make it easy to extract the three pieces that were screwed together (middle, top, and handle) out of the mold once the silicone had cured. In hindsight, these two pieces could have been made into a single piece but that was not obvious to me at the time.

Figure 3: First attempt at the hardshell mold

Figure 3: First attempt at the hardshell mold

After a single use of the hardshell mold, multiple issues with its design were laid bare:

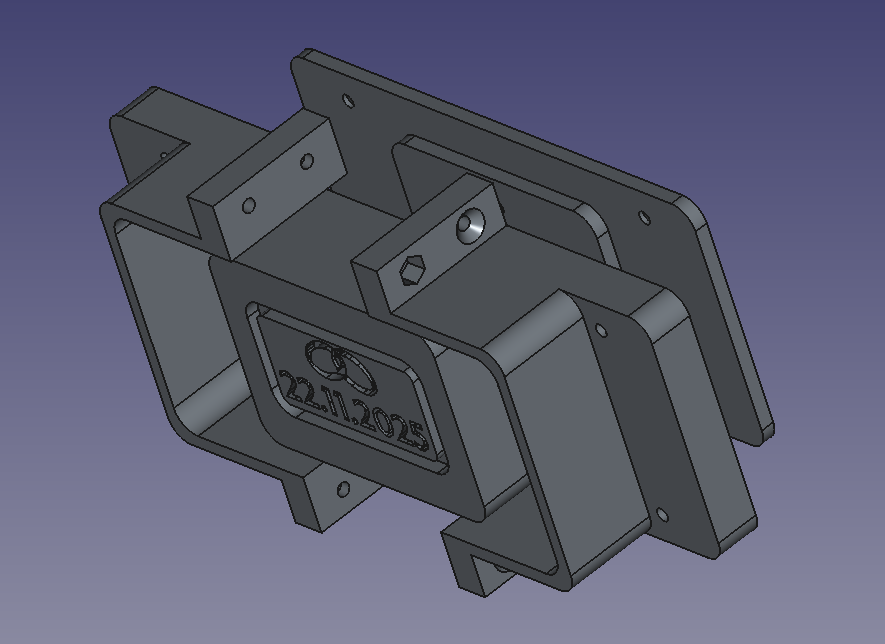

Figure 4: Assembled hardshell mold

Figure 4: Assembled hardshell mold

- The biggest issue was extracting the silicone mold once it had cured: The handle proved extremely weak, and broke right off. Additionally, the cured silicone was sticking so strongly to the “outer” and “inner” pieces of the mold, that it took wedging a screwdriver into the holes meant to pour the silicone in order to take the whole thing apart (if you zoom in on Figure 4 you can see the damage to the holes caused by this).

- The second issue was that some of the finer details of the imprint were not reproduced in the cured silicone. I believed this issue was due to the imprinted face of the “inner” piece of the mold having been designed to be facing down. In such design, the viscosity of the silicone would act against the silicone rising into the smaller pockets in the imprint and filling them as expected.

Figure 5: Improved hardshell mold design

Figure 5: Improved hardshell mold design

Because of these two issues, it was back to the drawing board. A couple iterations later, I had come up with the improved design shown in Figure 5 which addressed both issues above. The orientation of the mold was now flipped over, so that the imprinted face of the inner piece of the mold was facing up. This change would mean that gravity was working with, instead of against the silicone penetrating the narrowest pockets of the imprint. Furthermore, the outer piece of the mold was now split into two pieces which can be attached using screws, thus making for an easier extraction of the silicone once it was cured.

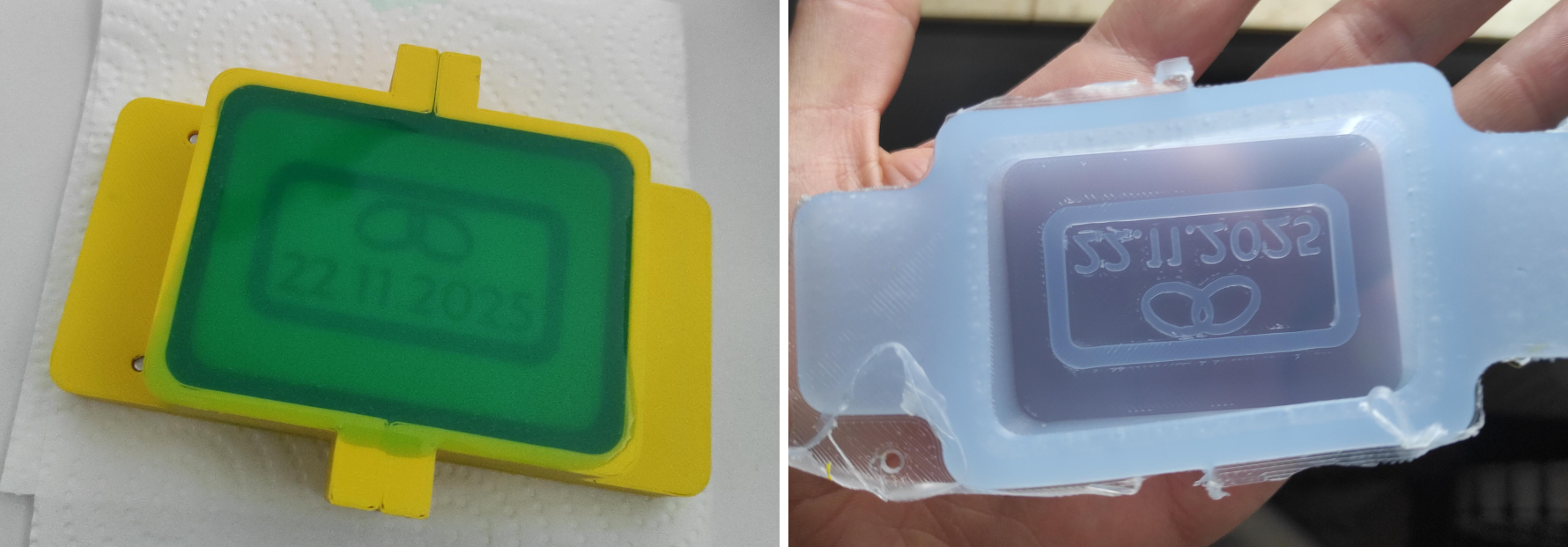

Figure 6 shows the mold in use (left) and the resulting soft silicone mold (right). I hope the difference in the silicone color between the two pictures in Figure 6 is not confusing. These are the only picture I had left of the mold making process, and I did not have the presence of mind to take pictures of the same mold while it was being made and after it was ready.

Figure 6: Using the hardshell mold to make the soft silicone mold

Figure 6: Using the hardshell mold to make the soft silicone mold

This iteration was already much better than the first design. However, it was still suffering from a couple issues. The first issue, is that after a few uses of the hardshell mold, I noticed that some bits of silicone tended to remain stuck in the smallest pockets of the imprint. This would result in subsequent soft-molds missing those details, and being of lesser quality. The second issue was the fact that this process only produces a single mold each time. If you remember, I needed to make 100 bars of soap, and I was aiming to produce 10 soft molds to be used by my wife to make the actual bars. My aim was to make a single platter-like silicone-mold which would make it possible to simply pour the liquid soap into it and wait for it to harden. Using 10 single molds instead of a single tray of 10 molds is possible but would be quite annoying I thought. Looking at my single mold design I didn’t think it could easily make a tray out of it. Furthermore, not being experienced with silicone, I assumed it would be tricky to have a uniform pour into such a complex form. I had to go back to square one and question my initial assumption:

Did I really need the intermediate silicone mold?

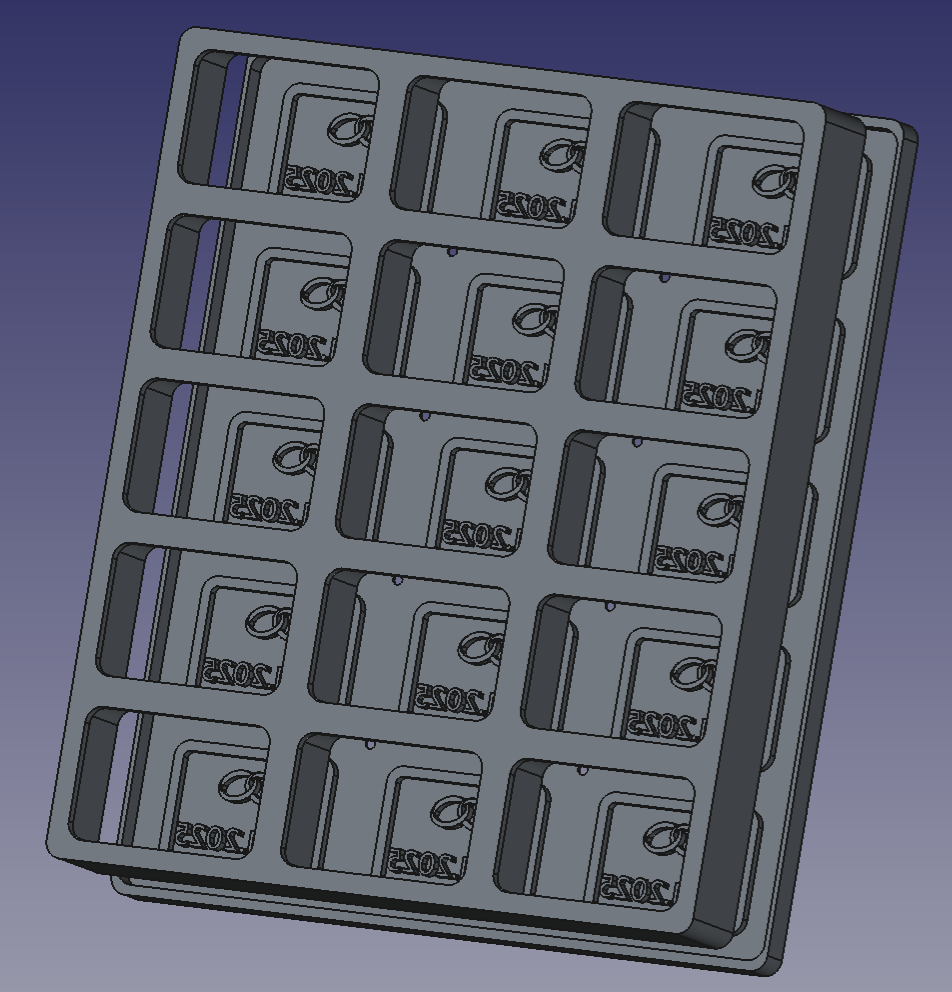

To test that theory, I made a new hardshell mold, this time destined to be used for making the bars of soap instead of the soft silicone molds. Because I didn’t have to take into consideration the intermediate step of making the silicone mold, this design could be much simpler than those I had made so far. My hope was that the design would be simple enough that I could easily expand it into a tray (which I found too complicated when silicone was involved).

Figure 7: Hardshell tray design

Figure 7: Hardshell tray design

The design of the hardshell tray ended up being quite straight forward. The mold is made of two pieces: A bottom plate which contains the imprints, and a top part which separates the volume of the mold into separate compartments, one for each bar of soap. The two parts are secured to each other using eight screws located in the eight junctions at the center of the mold. The top part was designed with pockets which house M3 hexagonal nuts, which are to be placed using the same principle as the first iteration of the hardshell mold. The imprints on the bottom plate were formed by first designing a single imprint, and then making use of FreeCAD’s LinearPattern feature to create the remaining ones. The size of the tray (and number of bars it contains) was dictated by the size of my printer’s printbed.

Figure 8 shows the tray in use: On the left is a top view of the mold after being filled with melted soap. On the right is a view of the hardened bars of soap after removing the bottom plate. During the first use of the mold, removing the bottom plate was quite hard as the soap was sticking to both parts of the mold. After a lot of persistence I was able to take the mold apart. However, it took me the best part of 10 minutes to do so, and by the end my fingers were very sore: There was no way I was going to repeat this process nine more times. Thankfully, after some googling I stumbled across the suggestion of oiling the mold before pouring soap into it. I was skeptical at first as I was scared I would end up with greasy soap bars, thankfully that ended up not being the case, and using oil ended up making the mold disassembly much easier.

Figure 8: Using the hardshell mold to make the soft silicone mold

Figure 8: Using the hardshell mold to make the soft silicone mold

At the end, I was quite satisfied with the end-result. The fact that the tray allowed for 15 bars of soap at a time was a great helper. It took an average of 1.2Kg of soap to fill the tray, and because we found that to be a good amount for a “single batch”, I did not even need to make a second tray.

Decorative lamp

As mentioned previously, this gift was the one I was most looking forward to design, as I thought it would give me an opportunity to get my soldering iron out of the storage box it had been sitting in for years now. Here again, I started scouring Printables.com for inspiration, until I came across the Lithophane Light Box design by Siah Yee Long. There were a lot of things I like about the design. It was simple, it used readily available components (LED strips and a USB-C port), and the designer had made a really nice guide to accompany his design. There were however some things I thought could be improved about the design. First of all, I found the frame to be way too thick for my liking. I also thought the frame could be made more stable by giving it more pronounced feet. Finally, I thought a simple switch would be easy to add to the design to enable its powering ON and OFF without having to unplug the USB cable.

The Front Plate

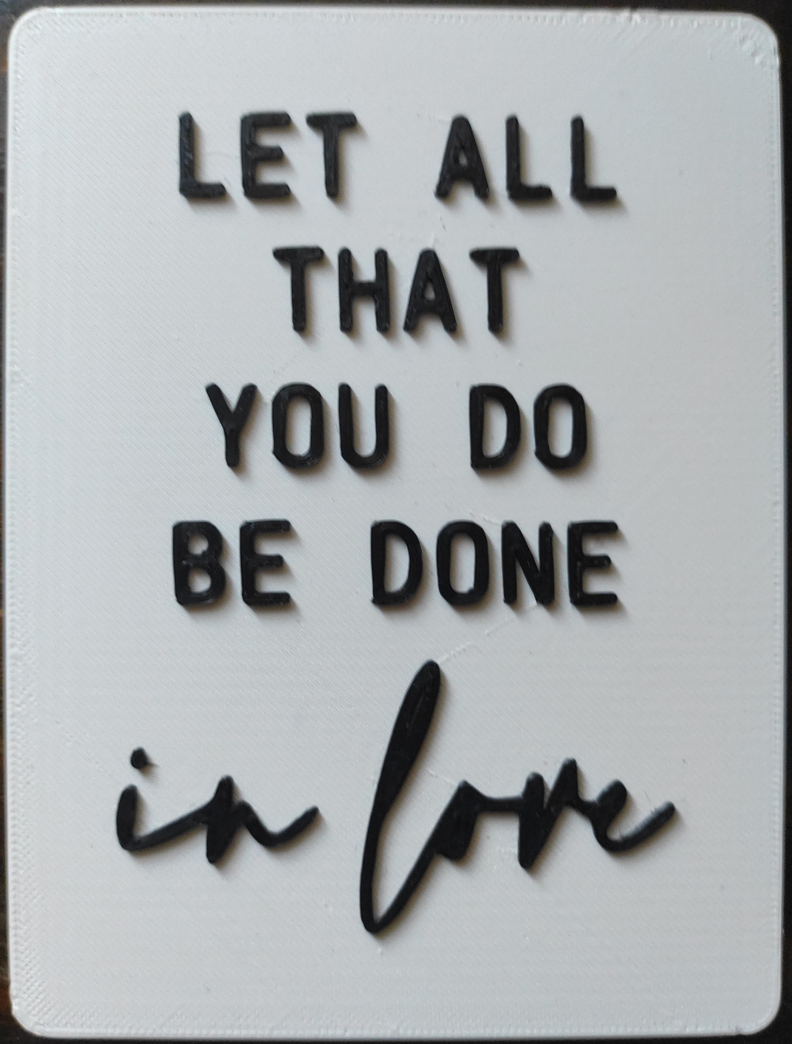

I will get to my design of the frame in a bit, but before that, I would like to introduce the iterations the front plate went through. As I mentioned when I first introduced the gifts, the idea was to use the invitation design as a starting point, simplify it a bit (e.g. removing most of the text), and feed the resulting image into a lithophane generating program (e.g. ItsLitho.com).

The left half of Figure 9 shows the image I used for the first iteration of the front plate. The right half, shows the resulting lithophane plate.

Figure 9: Using the hardshell mold to make the soft silicone mold

Figure 9: Using the hardshell mold to make the soft silicone mold

As you can see, the result is less than stellar. Specifically, the finer details of the source image are less visible in the printed plate, and they even cause horizontal artifacts which lower the perceived resolution of the plate. Furthermore, the high contrast between the dark background and the very bright details in the source image is completely lost in the resulting plate. I tried to remove some of the more problematic details and even delete the dark background from the source image, but I was not anymore satisfied with the end result.

Figure 10: Final iteration of the lamp front plate

Figure 10: Final iteration of the lamp front plate

At this point, I realized I had to lower my expectations and figured it would be much easier to design a simpler plate which would consist of a simple written message on the front plate instead of a complex image.

Funnily enough, this simpler design came with a lot of unexpected benefits. First of all, whereas the details of the original lithophane plate I had in mind would have only been visible during the night when the lamp would be turned on, the black text of the final design was clearly readable in the light of day, making it possible to use the lamp as decoration during the day when it would be turned off. Additionally, because there were no more fine details in the final plate, I could rest assured that the quality of my prints would remain consistent across the one hundred units I was to make. Finally, the plate could now be much thinner than required by a lithophane design. In fact, I found that a thickness of 2mm for the plate itself and 1mm to 2mm height for the text achieved a very satisfactory light diffusion effect. The text in question I ended up settling on is quote which my wife and I both agreed would be a great reminder of our special day.

The Frame

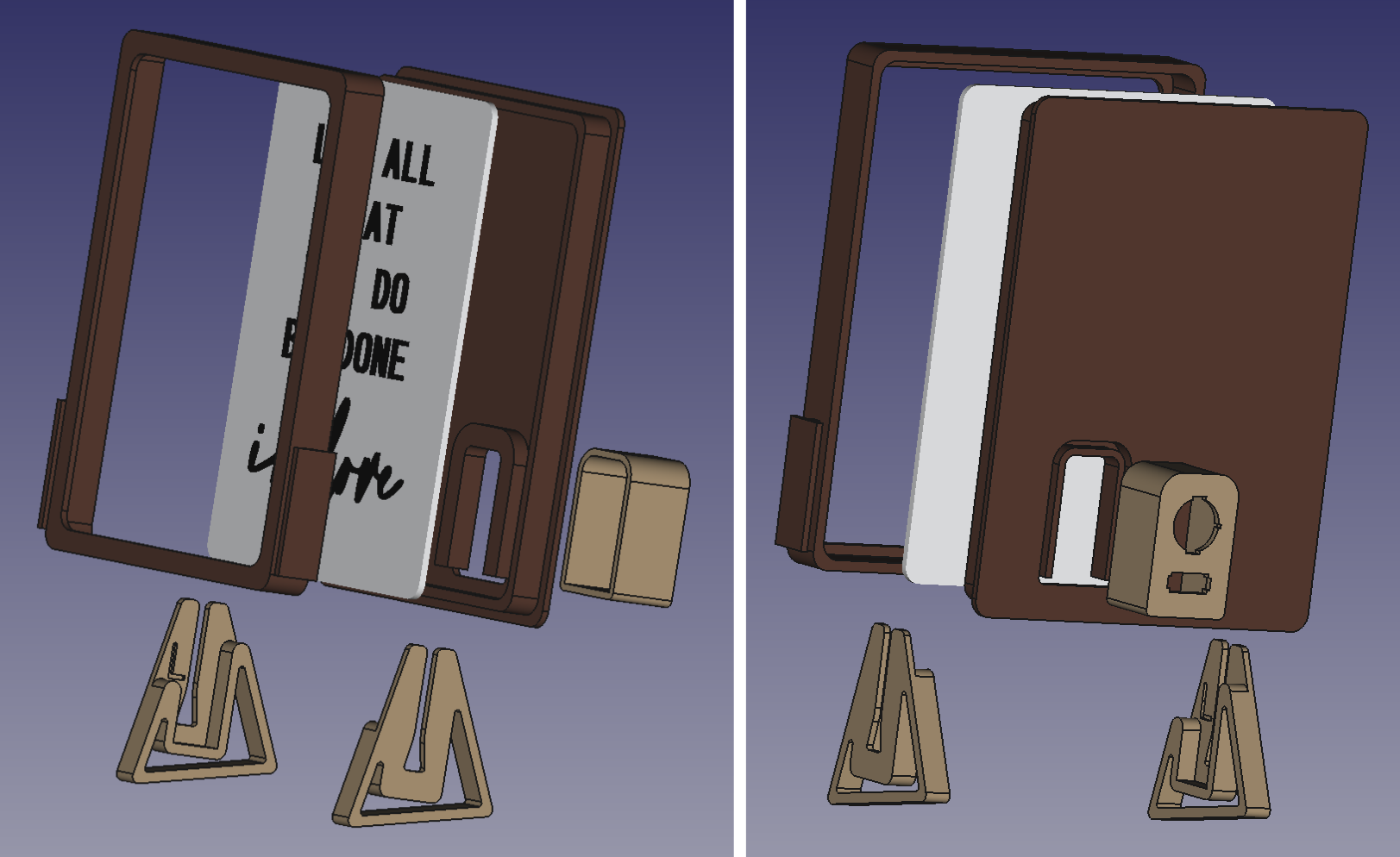

I don’t think there is much to say about the design process of the frame, but after multiple iterations, the design I ended up using is shown in Figure 10 The list of features I included in my design is as follows:

- I tried to make the whole thing as thing as possible. The actual frame clocks in at just

15mm(not including the feet of course). - The design now include two separate feet which serve a double purposes. First of all, they make the frame much more stable. Furthermore, they introduce a

15°tilt angle, making the frame much more comfortable to look at. - No screws, clips or similar components are required for the assembly. The front plate along with the back section of the frame slide into the front section. Due to the intentional lack of tolerances in my design, this assembly is on its own sturdy enough. Finally, sliding the feet into the assembly locks the back and front sections of the frame into each other making the final build very sturdy.

- The design now includes a slot into which a switch can be mounted. The switch slot, along with a slot for a UCB-C port are both present on a small separate back-piece which is “press-mounted” into the back section of the frame.

- The design being split into multiple pieces makes it very 3D-printing friendly and does not required any supports.

Finally, a detail that I have removed from the renders of Figure 11 is a signature I had imprinted on the back of the frame with my wife’s and my initials and the year of our wedding.

Figure 11: Final iteration of the lamp frame

Figure 11: Final iteration of the lamp frame

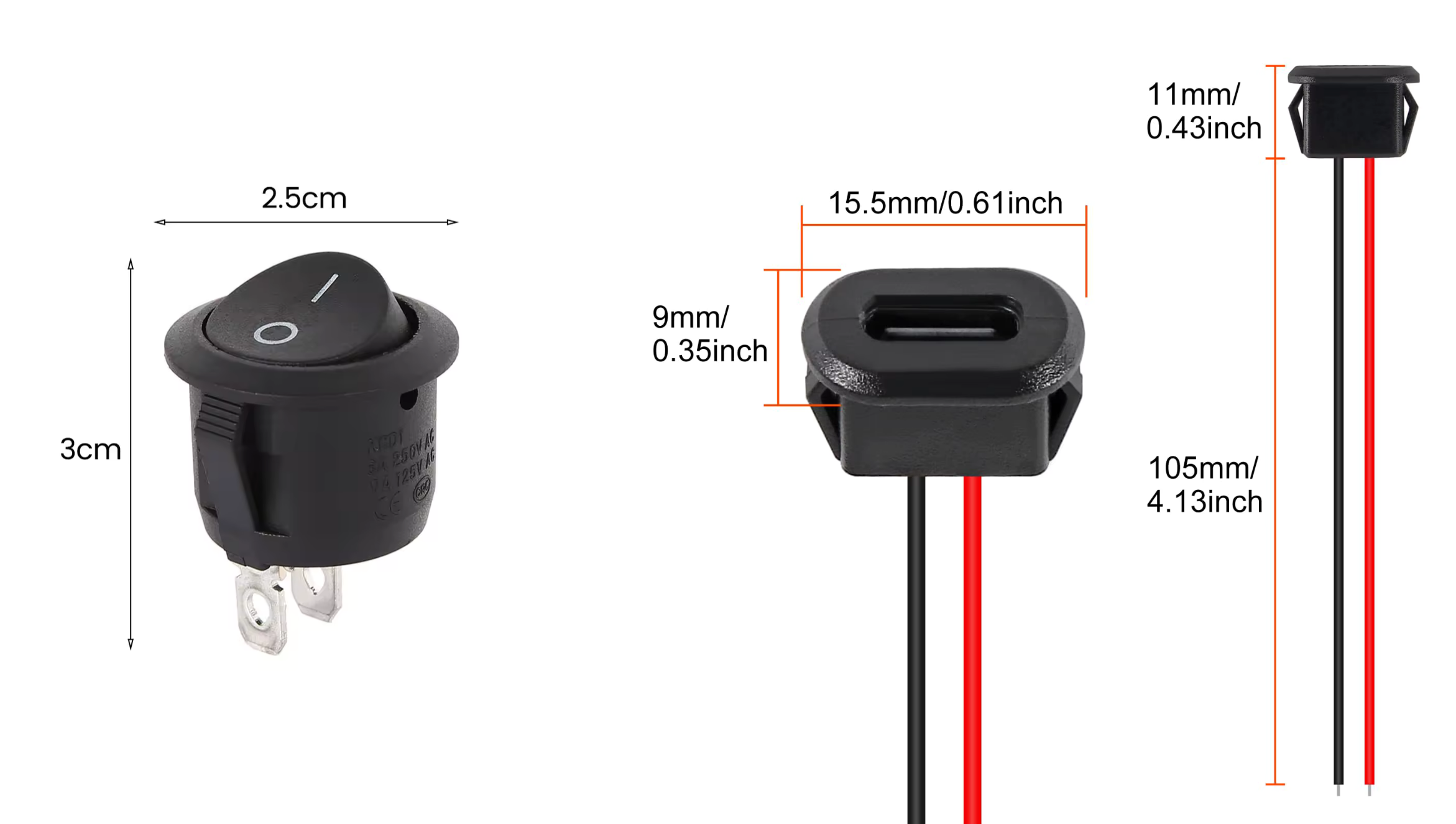

The Electronics

I have yet to mention anything about the electronics. I am not sure if there is a standard size for either the kind of electric switch or UCB-C port I ended up using. My choice was simply motivated by availability. At first I went on Amazon, but was quickly chased away but the high pricing (especially considering I was looking at ordering a hundred units of each). Looking into AliExpress yielded much cheaper results (including shipping). Figure 11 shows the dimensions of both components. I would have attached a link to the seller I used for my order, however, it seems their shop is no longer available on AliExpress.

Figure 11: Final iteration of the lamp frame

Figure 11: Final iteration of the lamp frame

When it came to the LED strip, I used one with a width of 5mm a warm color (3000K) and which came with a diffuser rather than bare LEDs. Because I could not afford the longer delivery time, I had made my order from Amazon (link to the exact model), though similar models with a much lower price tag are available on AliExpress.

Figure 12 shows the frame of the lamp with the switch, USB-C port and LED strip mounted.

Figure 12: Frame with assembled electronics

Figure 12: Frame with assembled electronics

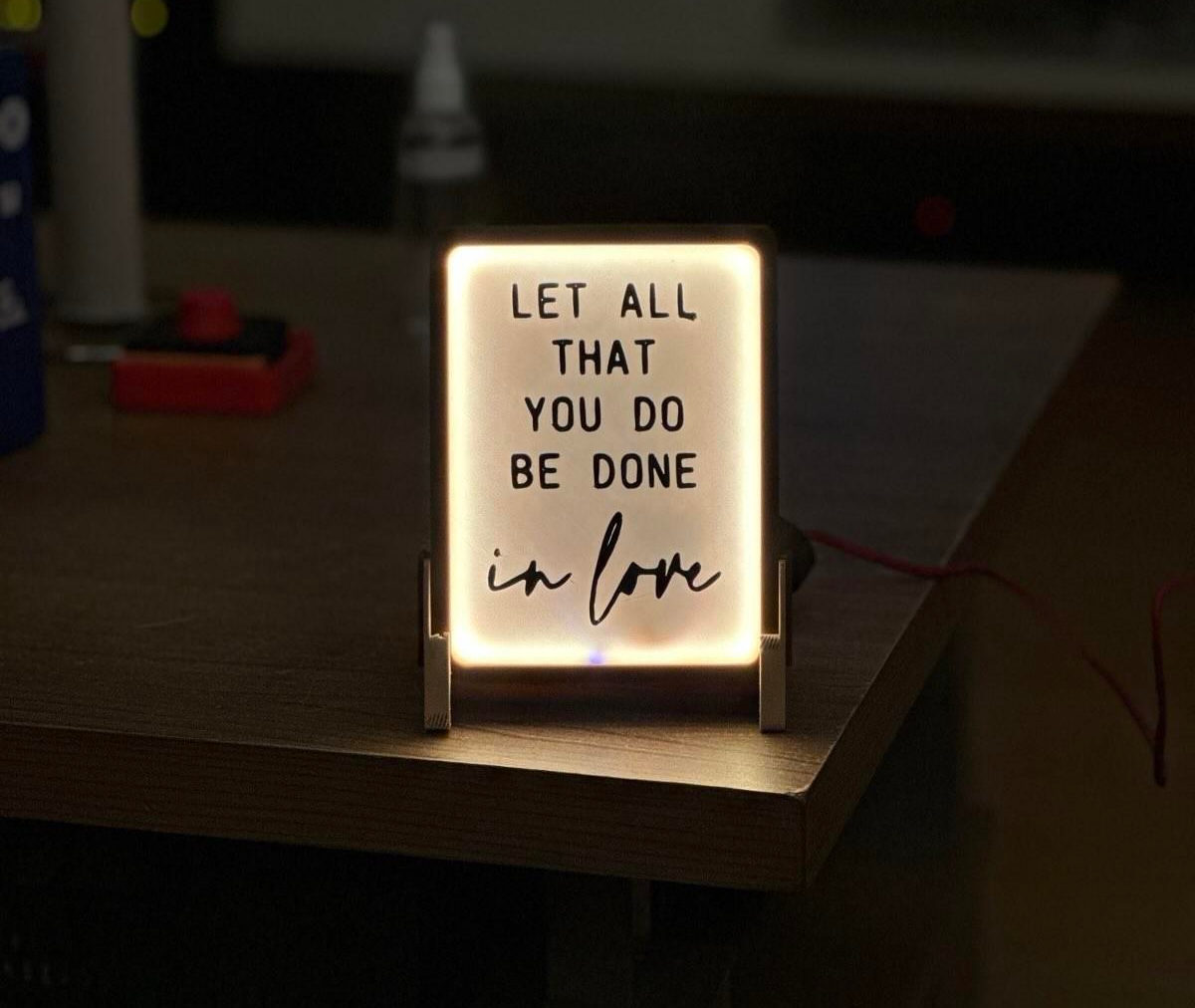

Final result

Figure 13: Decorative lamp final assembly

Figure 13: Decorative lamp final assembly

Figure 13 shows the assembled lamp in use. All in all, I think the result did not turn out bad at all. I really like the fact that it does not require any additional tools or components to be assembled. Its ease of print has been a godsend after the umpteenth hour of printing. Furthermore, its modularity allows for the front panel to be easily switched for a custom design. Finally, tweaking the model into landscape mode in addition to the portrait mode design I had decided on was straight forward. Figure 14 shows some of the different front panels I made using online lithophane generators. I have also uploaded the designs to my Printables profile.

Figure 14: Different designs of the front panel

Figure 14: Different designs of the front panel

Lessons learned

All and all, I have come out of this experience with many valuable lessons. Hard deadlines are nothing new to me (be it through studies, work, or personal life), and in such situations, I would always cope with the pressure by keeping my cards close to the chest. However, this time, knowing that my wife, and her family (now also my family) all had high expectations for what I would come up with, meant that I could not rely on my usual coping mechanism. Instead, the following two concepts helped me weather the most stressful times of the multi-week journey of designing, followed by the multi-month ordeal of printing and assembling:

- Design iteratively: The first design does not need to be the final one, and is almost never is. It sounds stupid to make such a statement, as it sounds so obvious. However, the moment I started naming my CAD files Draft_X.YZ, a lot of the pressure of needing to make that design perfect went away.

- If it doesn’t work, lower your expectations and try again. I have to admit that I stole this one from Shane Wighton from the Stuff Made Here Youtube channel. I ended up re-watching a lot of his videos while working on the different gifts. Watching him reiterate this concept time and time again as he navigates the complex challenges he faces in his projects cemented this as a new rule of mine.

I think these two rules helped me the most while designing the soap mold: At first, designing a whole tray seemed unsurmountable to me, so I lowered the bar to designing the mold for a single bar of soap. Once I was able to create that simpler design, iterating on it, and creating a whole tray was much more manageable.

Conclusions

There is a lot more I wish I could have mentioned in this article. The financial aspect of making the gifts, the logistics of ordering the electrical components for the lamp, the few 24h non-stop printing days, and the fact that my wife and I had to transport all hundreds of gifts in our luggage by plane. However, this article has grown in size much more than I had originally anticipated, so to cut a long conclusion short, I will say the following: This experience has been totally worth all the trouble. The lessons learned, and the sense of accomplishment feel like wind in my sails, and I would like to keep this momentum going, and keep improving my 3D CAD skills. On the other hand, looking back at the stress this ordeal has caused me, I think it is safe to say that I am definitely not getting married again any time soon.